2022-11-25

2022-11-25

Bridge guardrail pouring

Mix proportion: In order to ensure the smooth and beautiful surface of the guardrail concrete, it is very important to use cement and mix proportion. After many attempts, the following mix proportions are used: water: cement: sand: 0.5~1cm small stones: 1~2cm large stones (0.5:1:1.74:1.52:1.85). The cement is Dushi 525 # ordinary Portland cement produced by Jidong Cement Plant. The cement consumption is 370kg, the sand ratio is 34%, and the concrete slump is too large, The concrete is prone to bleeding, the surface is not smooth and clean, and the water mark is obvious; If the slump is too small, it is not easy to vibrate and compact, and there are many honeycombs and bubbles. The raw materials for concrete are strictly required. Sand and small stones must be screened, and the dosage must be accurate and in strict accordance with the mix proportion.

Concrete mixing

The mixer operator shall strictly control the water consumption, and the mixing time shall not be less than 3min to ensure that the concrete is evenly mixed and the slump meets the requirements, and the mixed concrete has good workability. Pouring concrete: the concrete shall be poured in three layers. The first layer is poured to the lower part of the bevel at the bottom of the guardrail, the second layer is poured to the upper corner of the bevel, and the third layer is poured to the top. The vibrator controls the time and volume of the three layers of concrete. The concrete shall be evenly distributed, and the vibration time shall be strictly controlled. The vibration time of each layer of concrete shall be no less than 1min and no more than 1.5min.

Grout collection: after the completion of the concrete pouring of the guardrail, the top surface adopts three times of mortar collection. For the first time, use a wood trowel to smooth, for the second time, use an iron trowel to smooth, and for the third time, use a roller to smooth when the concrete is initially set.

Formwork removal: the formwork removal is based on the temperature and concrete strength, and the non bearing members can be removed after 10-20h. After the formwork is removed, it should be dried in the shade for half a day (mainly to ensure the color is consistent). The bubbles should be blocked up with cement slurry mixed with white cement and covered with grass curtains (or other coverings) that do not pollute the concrete. It is not suitable to spray film curing agent.

matters needing attention:

Precautions during construction of bridge guardrail

1. During the construction of guardrails, the data of various facilities shall be accurately mastered, especially the accurate positions of various pipelines buried in the subgrade. No damage to underground facilities is allowed during the construction. In case of insufficient filling depth of underground communication pipeline, drain pipe or culvert top, the position of column shall be adjusted or the fixing method of column shall be changed.

2. When the column is driven too deeply, it is not allowed to pull out the column for correction. It is necessary to pull out all the rest, tamp its foundation again, and then drive it, or adjust the position of the column.

3. Flange plate shall be installed for bridge guardrail, and attention shall be paid to the positioning of flange plate and the control of top elevation of column.

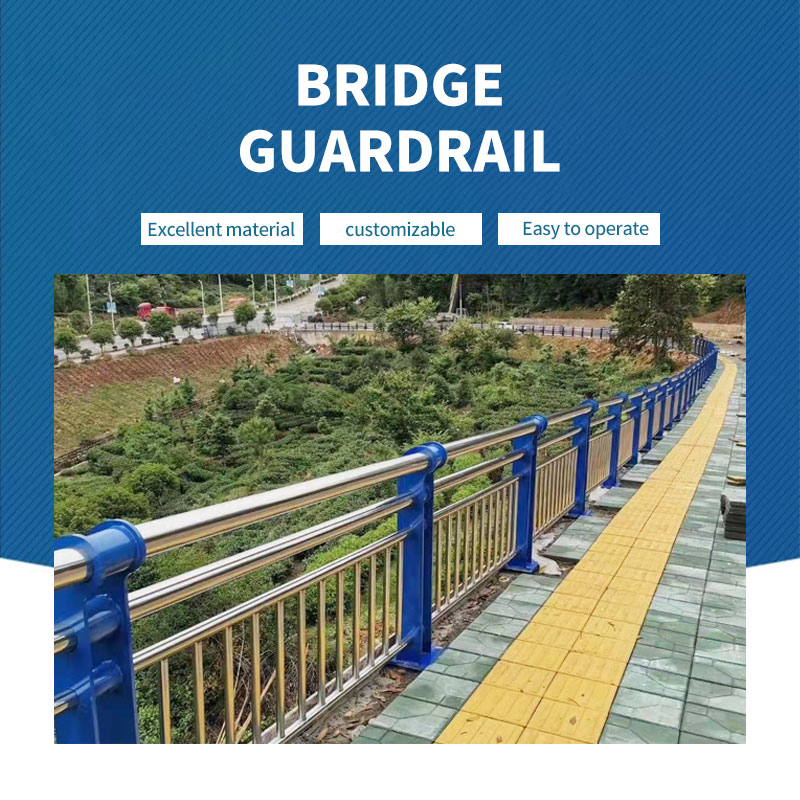

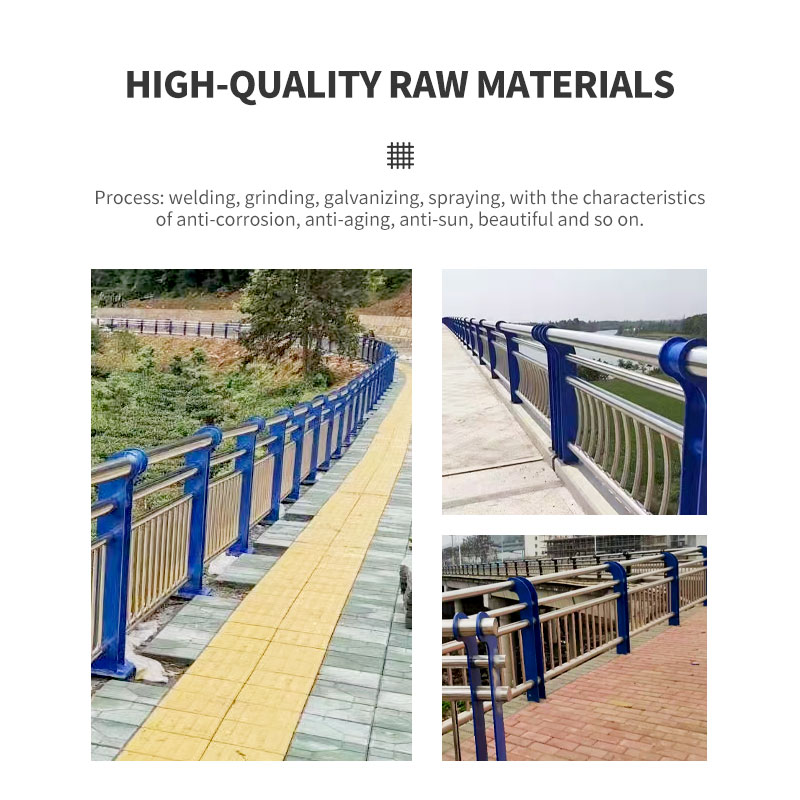

Bridge guardrail refers to the guardrail set on the bridge. Its purpose is to prevent the runaway vehicle from crossing the bridge, which has the function of preventing the vehicle from breaking through, undercrossing, crossing the bridge and beautifying the bridge building.

For the selection of bridge guardrail form, firstly, the anti-collision grade shall be determined according to the highway grade, taking into account its safety, coordination, characteristics of the object to be protected, site geometric conditions and other factors, and then the structural form shall be selected according to its own structure, economy, construction, maintenance and other factors. The embedding methods include column direct embedding, flange plate connection, and casting bridge guardrail and bridge deck into a whole through force transfer reinforcement. If conditions permit, the removable guardrail can be used.

There are many methods to classify the types of bridge guardrails. In addition to the location, they can also be classified according to the structural characteristics, anti-collision performance, etc. According to the setting position, it can be divided into bridge side guardrail, bridge median guardrail and guardrail at the boundary of pedestrian and lane; According to the structural characteristics, it can be divided into beam column type (metal and concrete) guardrails, reinforced concrete wall type guardrails and combined guardrails; According to anti-collision performance, it can be divided into rigid guardrail, semi-rigid guardrail and flexible guardrail. Common guardrails include concrete guardrail, corrugated beam guardrail and cable guardrail.

Sichuan Jinhengda Municipal Engineering Co., Ltd. was established on August 28, 2012. The legal representative is Liu Zhiyang. The company's business scope includes: municipal engineering design and construction; Design and installation of municipal facilities; Landscape engineering design and construction; Steel structure design and installation; Lighting engineering, urban and road lighting engineering, environmental protection engineering, earthwork engineering, foundation foundation engineering, metal doors and windows engineering, communication engineering, construction engineering, highway engineering, fire fighting facilities engineering, electronic and intelligent engineering, building decoration engineering, highway transportation engineering, river and lake regulation engineering construction; Construction labor subcontracting; Machinery leasing; Sales: traffic barriers, guardrail nets, metal wire mesh, flower boxes, plastic products, traffic safety facilities, guardrails, building materials, decorative materials, metal doors and windows, signs and markings; Processing, production and production (only branches are allowed to engage in production, processing and operation in the industrial park): steel structures, plastic products, traffic safety facilities, municipal facilities, guardrails, building materials, decorative materials, metal signs, metal doors and windows, and signs; Import and export of goods or technologies (except those prohibited by the state or involving administrative approval)

Zhiyang Liu

149825840@qq.com

koppsumpterf62313@gmail.com